Besides edge finishing, overlockers can also perform various stitches, including flatlock and chain stitches. Flatlock stitching is especially beneficial for activewear, as it lies flat against the skin and reduces irritation, while chain stitching offers flexibility and strength, making it suitable for stretchable fabrics. Many modern overlockers also come with adjustable settings, allowing users to customize the stitch width, length, and tension to suit different fabric types and project needs.

Home

Home

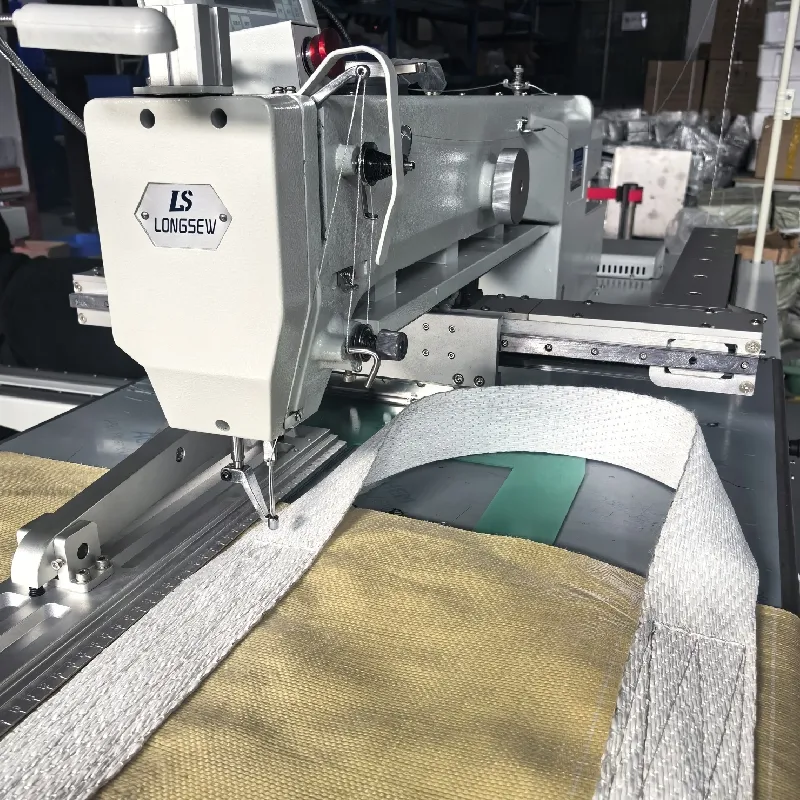

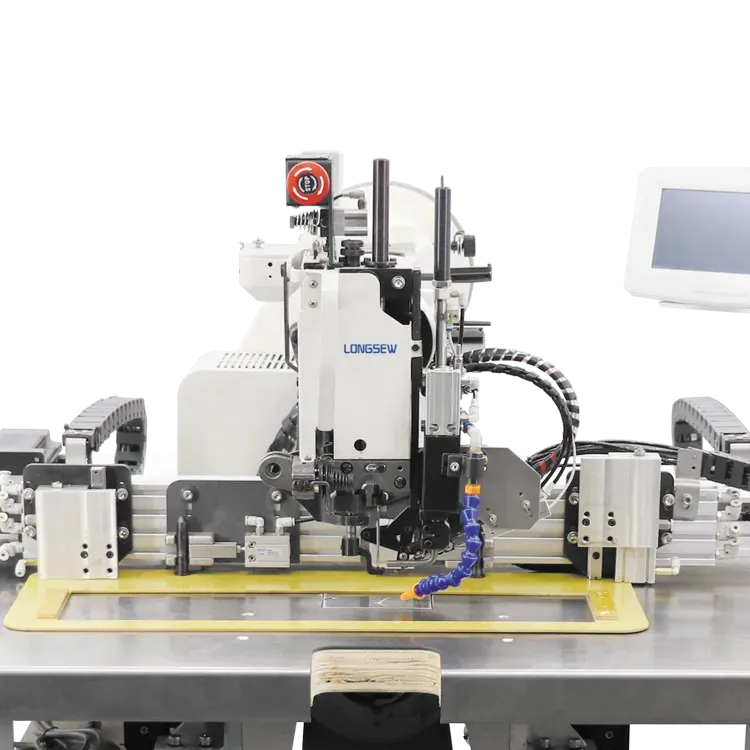

The machine is built to last, with a sturdy construction that can withstand hours of use The machine is built to last, with a sturdy construction that can withstand hours of use

The machine is built to last, with a sturdy construction that can withstand hours of use The machine is built to last, with a sturdy construction that can withstand hours of use